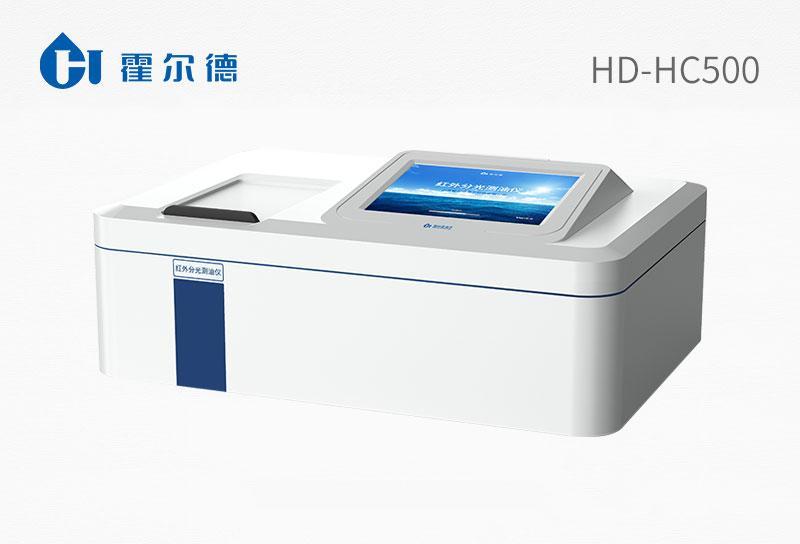

Fully automatic UV oil tester

manufacturer:Shandong Horde Electronic Technology Co., Ltd.

Introduction:The manufacturer of Fully automatic UV oil tester「Horde Electronic」 has mastered the research and development technology of Fully automatic UV oil tester, with more than 10 years of experience in manufacturing Fully automatic UV oil tester. The quality is reliable, the detection accuracy is high, and the price competitive advantage of the source manufacturer is obvious. Welcome to call for more information.

Update time:2025-12-14

- Contact: Contact Information

- Phone:008619053605658

Product Recommendation

Product Details

Product Overview

The HD-QH600 fully automatic UV oil meter is developed and manufactured according to China's environmental protection standards. The instrument is a special UV spectrometer for detecting the oil content in water. It can be used to detect the oil content in surface water, groundwater, and industrial wastewater.

Application Fields

The fully automatic UV oil meter can be widely used in water environment detection systems, sewage treatment plants, water companies, petrochemicals, university research institutes, hydrology and water conservancy, metallurgy and steel, biomedicine, agricultural environment monitoring, wool textile printing and dyeing, marine environment monitoring, papermaking, and other fields of water quality detection.

Features

1. Conforms to the Chinese Environmental Protection Standard "HJ970-2018" for the determination of water quality petroleum by ultraviolet spectrophotometry;

2. Automatic sampling, extraction, water removal and filtration, magnesium silicate adsorption, measurement, drainage and cleaning, can continuously make 6-12 samples, and realize automatic detection;

3. The extractant is fully enclosed in all links such as liquid storage, sample extraction, testing and waste discharge, reducing the chance of operators contacting harmful reagents, which is safer;

4. Real-time monitoring of reagent residue, insufficient reagent, can provide early warning function;

5. The oil-water separation membrane is used instead of anhydrous sodium sulfate to absorb trace water, eliminating the step of frequent replacement of anhydrous sodium sulfate, which is more convenient to use and easy to maintain;

6. The instrument has a self-designed magnesium silicate addition technology that meets the national standard requirements and avoids the occurrence of easy blockage failures;

7. The instrument adopts a special downward pressure stirring extraction technology, which has higher extraction efficiency;

8. The instrument uses Win7 Flagship operating system, built-in Holder Electronics special analysis software, special analysis software, integrating spectrum, scanning, analysis and calculation;

9. The instrument has a built-in 8-inch touch tablet computer and an external wireless mouse and keyboard operation, which is simple, convenient and fast;

10. Standard curve calibration, users can also establish standard curves by themselves;

11. The dilution and enrichment ratios can be set arbitrarily;

12. The service life of the light source can reach more than 10,000 hours. The light source uses electrical modulation and light source technology to prevent the internal temperature of the instrument from being too high and affecting stability;

13. It has automatic statistical analysis, spectrum scanning display, storage, printing and other functions;

14. The instrument has 30G storage space and can store 1 billion groups of historical data;

15. Quick data query can be performed by time, sampling location, and sampling personnel, and the test data can be printed;

16. The entire pretreatment system uses fully anti-corrosion and non-oil-philic materials, and uses air self-cleaning cleaning flow The process can minimize the cross-influence of high and low concentration water samples;

17. The front end of the instrument adopts a molecular sieve structure to prevent impurities from clogging the pipeline;

18. The sampling bottle is a sample bottle with a scale display. It can directly and accurately measure and collect water samples. There is no need to transfer water samples. It can be directly tested on the machine;

19. The tested water samples and solvents are automatically discharged into the waste liquid barrel by blowing. There is no residue in the pipeline and it does not affect the test of the next sample;

20. The instrument has an automatic dilution function, which can identify unknown high-concentration samples and automatically dilute according to the set over-concentration threshold;

21. The instrument is equipped with a mobile phone APP. Through the big data cloud, the mobile phone can control the instrument's operating status, fault warning, data approval query, and remote diagnosis functions;

Technical parameters

Basic measurement range: 0.0-800mg/L

Sample measurement range: 0~100% oil (enrichment and dilution)

Test wavelength: 225nm;

Absorbance Range: 0.0000~2.0000AU (i.e. transmittance 100~1%T)

Instrument detection limit: DL≤0.02mg/L (3 times SD of 11 times of tetrachloroethylene blank solution)

Method detection limit: 0.05mg/L;

Minimum detection concentration: 0.003mg/L;

Correlation coefficient: r>0.999;

Repeatability: RSD≤0.2%;

Accuracy error: ≤2%;

Automatic detection time for a single sample :2-8min;

Test sample quantity: 6-12 samples can be tested continuously;

Wave number accuracy and repeatability: ±1cm-1;

N-hexane extraction volume: 10-25ml integer multiple;

Using temperature and humidity: temperature range 1℃-40℃, humidity ≤90﹪;

Main unit dimensions: 620mm×480mm×620mm (length, width and height);

Power supply: (220±22)V, (50±1)Hz, 50VA;

Product's Website:http://en.huoerd.com/cyy/938.html

中文版

中文版 English

English

Home

Home Phone

Phone Product

Product Contact

Contact