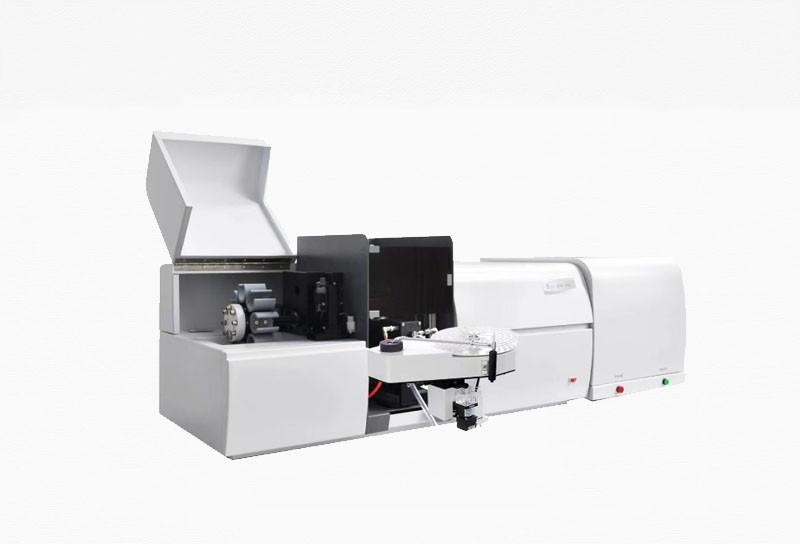

Fully automatic atomic absorption spectrometer

manufacturer:Shandong Horde Electronic Technology Co., Ltd.

Introduction:The manufacturer of Fully automatic atomic absorption spectrometer「Horde Electronic」 has mastered the research and development technology of Fully automatic atomic absorption spectrometer, with more than 10 years of experience in manufacturing Fully automatic atomic absorption spectrometer. The quality is reliable, the detection accuracy is high, and the price competitive advantage of the source manufacturer is obvious. Welcome to call for more information.

Update time:2025-12-14

- Contact: Contact Information

- Phone:008619053605658

Product Recommendation

Product Details

1. Product Introduction:

All functions of HD-AAS8HS-P flame graphite furnace integrated atomic absorption spectrometer are controlled by PC, equipped with automatic sample injector to realize full automatic control, without manual supervision. Unique optical mechanical design, safe and convenient flame system, advanced graphite furnace temperature control technology, optional background subtraction technology, and various convenient functions provided by the workstation meet your pursuit of automation for precise measurement.

2. Application Field:

It can be widely used in geology, metallurgy, medicine, chemical industry, petroleum, agriculture, environmental protection, commodity inspection and other industries. The analysis and application of trace elements has gradually penetrated from inorganic chemistry to organic chemistry in recent years.

3. Performance characteristics

1. Eight-lamp flame graphite furnace all-in-one machine (high-performance element lamp is optional), automatic three-dimensional switching, energy balance, multi-lamp preheating at the same time to save waiting time, with atmosphere lamp background buckle l self-absorption background buckle function;

2. Unique integrated design of flame atomizer and graphite furnace atomizer, realizing automatic switching and manual switching dual modes;

3. Automatic optimization memory function of instrument setting conditions, one-click completion of scanning peak search and energy balance;

4. Multi-format storage and print output of data reports, convenient data query and comparison;

5. The instrument software adopts a single-interface multi-function window design, making operation simpler, real-time monitoring of data changes, support for mainstream Windows operating systems, support for remote control and calibration, Chinese/English versions optional, with comprehensive quality control (QC) function;

6. Advanced and reliable multiple safety protection system, automatic detection, alarm, such as insufficient pressure, leakage, flameout and other abnormal conditions;

7. Domestic advanced technology graphite furnace atomizer real-time monitoring, including visual system equipment Full-color high-definition camera system, real-time monitoring of the injection needle in the graphite tube, sample solution drying, ashing process, etc., including timely adjustment of graphite furnace conditions to extend the service life of the graphite tube;

8. The automatic sampler system can realize automatic configuration of standard curves, automatic dilution, and high-precision injection. ※Expandable: hydride system and combined functions;

9. Equipped with an automatic sampler to achieve fully automatic detection function without manual supervision;

4. Technical indicators:

1. Optical system

Wavelength range: 190~900 nm;

8 lamp positions: no need to replace lamps for multi-element analysis;

Wavelength repeatability: ±0.1nm;

Wavelength accuracy: ±0.2nm for the entire band;

Absorbance range: 0~2.5ABS;

Resolution: spectral bandwidth of 0.2nm can separate the manganese double line (279.5 and 279.8) and the valley-peak energy ratio is <20%;

Spectral bandwidth (6 levels): static baseline drift 0.1nm, 0.2nm, 0.4nm, 0.7nm, 1.0nm, 2.0nm, ≤0.002ABS/30min(Cu);

Number of gratings: 1800 lines/mm;

D2 background subtraction method: when the background signal is 1ABS, the background subtraction ability is ≥50 times;

2. Flame atomization system

Air-acetylene flame combustion head: 100mm;

Ignition dynamic baseline drift: ≤0.004ABS/30min(Cu);

Sensitivity (Cu) characteristic concentration: ≤0.025ug/ml/1%;

Relative standard deviation: ≤0.5% (Cu, absorbance>0.2ABS concentration 1ug/ml);

Detection limit (Cu≤0.004ug/ml) : Automatically cut off the gas when the pressure is insufficient, the power is interrupted, the flame is abnormally turned off, and the combustion head does not match;

3. Graphite furnace atomization system

Graphite furnace working temperature: room temperature ~ 3000℃;

Maximum heating speed: ≥2000℃a/s;

Characteristic quantity: Cd≤1pg, Cu≤10pg;

Relative standard deviation of precision: Cd≤3%, Cu≤3%;

Heating temperature control method: power control in the drying and ashing stage, light control maximum power temperature control in the atomization stage;

Safety: overcurrent protection/protection gas pressure insufficient alarm/automatic stop of heating/cooling water flow insufficient alarm/automatic stop of heating;

Power supply: 220VAC;

Power: 7000w;

Automatic sampler: 85 bits, automatic configuration of standard curve, automatic dilution function, high-precision injection;

Product's Website:http://en.huoerd.com/yzxsfggdj/1791.html

中文版

中文版 English

English

Home

Home Phone

Phone Product

Product Contact

Contact